What are the properties of compact hpl 12mm?

Dec 22, 2022|

Dec 22, 2022| View:221

View:221Laminates are produced using a lamination process, which is a comprehensive technology involving many factors such as plastic films, adhesives, solvents, the condition of the substrate surface undercoating, mechanical control, and environmental conditions. To achieve a high-quality compact hpl 12mm, it is necessary to control the variation of these factors during the process and to harmonize their relationship with each other.

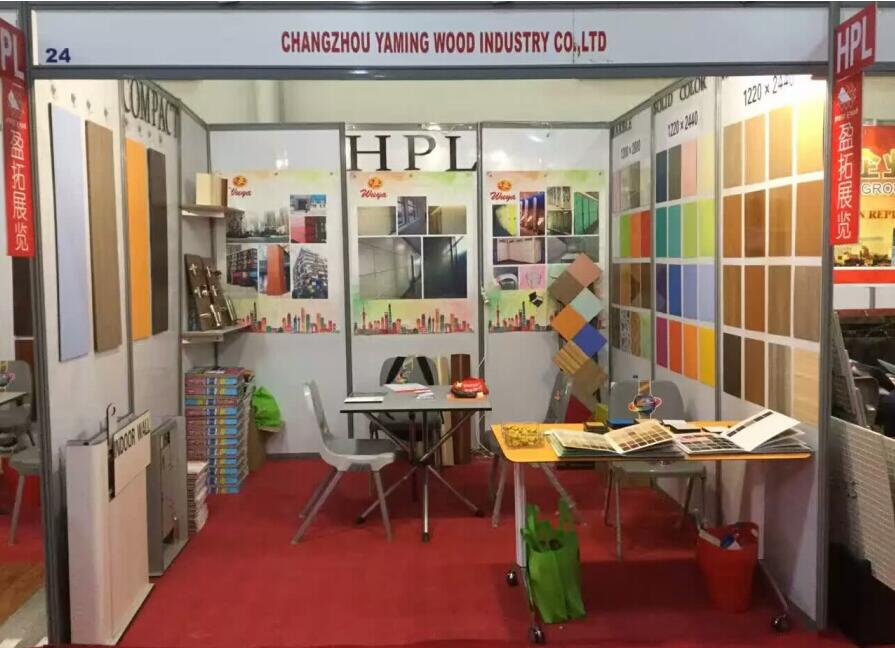

The base material for compact hpl 12mm can be cold rolled steel, galvanized steel, or other coated steel, and the surface coating material is plastic or resin film. compact hpl 12mm, therefore, combines the properties of both steel and plastic in terms of use and decoration, mainly in the following ways.

1. Particularly resistant to moisture and water. Suitable for use in wet conditions.

2. Good formability. After cold-forming, there is no paint loss at the bending roller extrusion.

3. Due to the wide range of colors available in plastic films after overprinting, the variety of colors available in compact hpl 12mm is incomparable to that of coated panels.

4. Compact hpl 12mm is a plastic film laminated under a certain pressure, with a strong film layer and high bond strength. This, together with the use of steel sheets as a substrate, has led to an increasing number of facade panels using compact hpl 12mm as an alternative to coated panels.

The lamination process is an important tool in the manufacture of laminated products. Currently, there are several ways of using the lamination process for the adhesion of metal sheets to plastic films, such as wet lamination, dry lamination, hot press lamination, and cold press lamination.

The above is the introduction of compact hpl 12mm, hope it can help you better understand our products, if you have other questions or needs, welcome to contact us directly.