How can chemical resistant laminates be processed and printed?

Jun 14, 2023|

Jun 14, 2023| View:1300

View:1300As a leading manufacturer of chemical resistant laminates, we are often asked how these materials can be processed and printed. In this article, we will explore the process of processing and printing chemical resistant laminates.

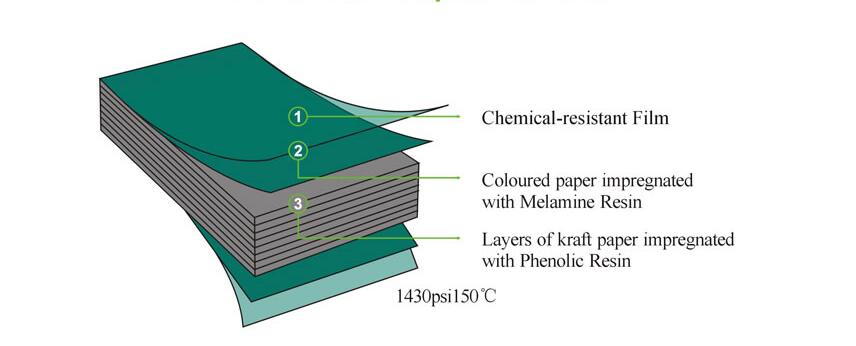

Chemical resistant laminates are a type of laminate that is designed to be resistant to various chemicals. These materials are often used in a variety of industries, such as food processing, medical, automotive, and electronics. Due to their exceptional properties, chemical resistant laminates are becoming increasingly popular.

Process of Processing Chemical Resistant Laminates

To process chemical resistant laminates, the material first needs to be laminated. The lamination process involves applying a layer of adhesive to one surface of the laminate and pressing it against a second layer of material. The adhesive bonds the two layers together, creating a single piece of material.

Once the lamination process is complete, the chemical resistant laminate can be processed further. This can include printing, painting, or other processes to create a final product. The processing steps can vary depending on the specific application and the needs of the customer.

Printing Chemical Resistant Laminates

Printing chemical resistant laminates is a critical step in the processing process. Printing is used to create a variety of patterns, designs, and colors on the surface of the laminate. This can be done using a variety of techniques, such as gravure printing, offset printing, and screen printing.

To print chemical resistant laminates, the material first needs to be prepared. This involves applying a release agent to the surface of the laminate to prevent the ink from bonding to the material. The ink is then applied to the surface of the laminate, usually using a print head.

Once the ink has been applied, the laminate is pressed against a printing surface. This causes the ink to penetrate the surface of the laminate, creating the desired design or pattern. The laminate is then dried, usually using heat or steam, to ensure that the ink is fully absorbed into the material.

Conclusion

Processing and printing chemical resistant laminates is a critical step in the production of these materials. The lamination process creates a single piece of material, while printing adds a final touch to the final product. From food processing to medical applications, chemical resistant laminates are becoming increasingly popular and are playing a critical role in protecting against harmful chemicals.